X-Ray Computed Microtomography at SSEF

by Dr. F. Herzog & M.S. Krzemnicki, first published in Facette 20 (January 2013)

For the last few years SSEF has seen increased demand for analysis of pearls. This is not astonishing. On the one hand, the supply of natural pearls that grow or were grown without any human intervention is limited. On the other hand, the process of culturing pearls is getting more and more sophisticated such that the end products are sometimes very hard to distinguish from their truly natural counterparts.

For a gemmological laboratory it is therefore absolutely essential to have equipment that can resolve any ambiguities in the field of pearl origin (not in the geographical sense) as the price differences between these categories are substantial.

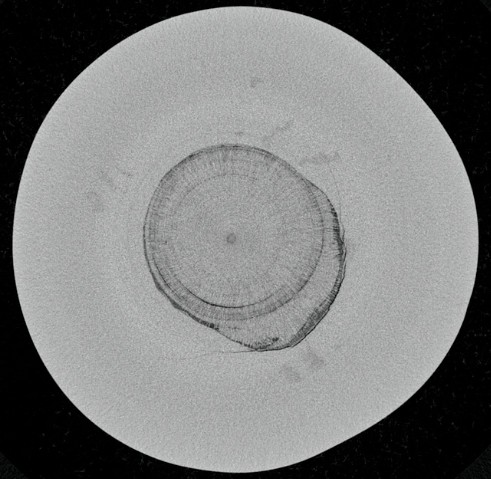

It is well known that pearl analysis is mainly based on two-dimensional X-ray radiographies, where growth-structures can be made visible and a separation of cultured from natural pearls is in many cases possible. These radiographies are two-dimensional projections and this alone may lead to ambiguities in their interpretation, as the position of a certain feature cannot be attributed to a certain depth along the projection path.

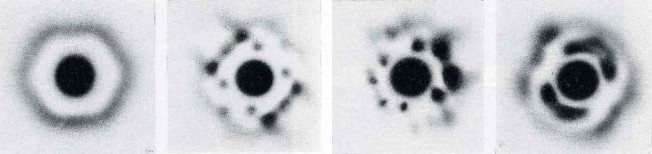

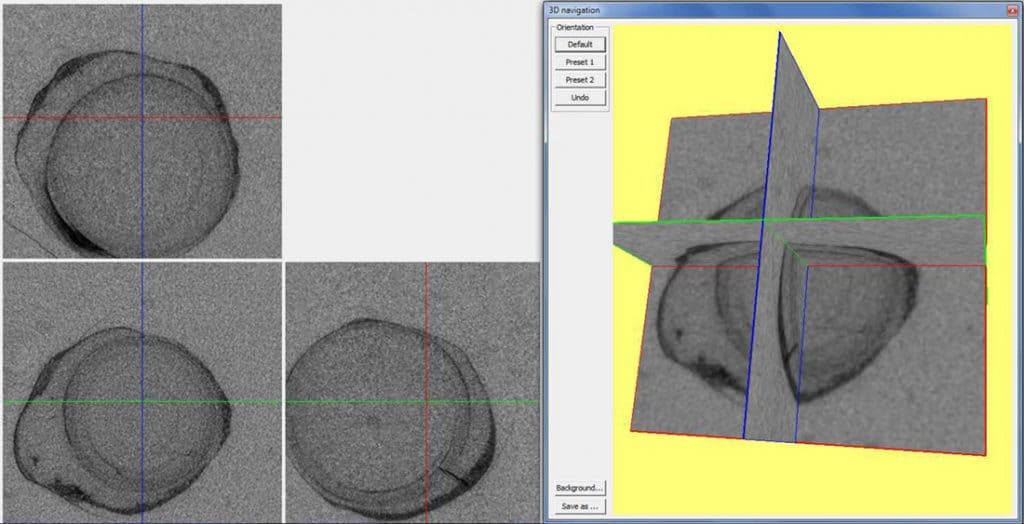

To eliminate this ambiguity X-ray computed micro-tomography (µ-CT) was proposed as a method in 2009 by several authors, and was integrated that same year into our SSEF pearl testing procedures (Krzemnicki et al. 2010). Digital geometry processing is used to generate a three-dimensional image of the inside of an object on the basis of a large series of two-dimensional X-ray images taken around a single axis of rotation. SSEF has closely followed these developments in technology and applied them to the testing of pearls when ambiguous growth structurest were seen in radiographies. Our tomography service comes at an additional cost but is well appreciated by our customers.

After having tested a number of instruments from different producers, we have decided to collaborate with Scanco Medical AG (www.scanco. ch), a Swiss high-tech company which not only provided us with a state-of the art instrument, but also with very scientific and professional support. Founded in 1988 as a spin-off of the Swiss Federal Institute of Technology (ETH) in Zurich, their systems integrate high-quality imaging with powerful 3D analysis tools, which perfectly meets our requirements for pearl analysis.

We are proud to have added their Specimen µ-CT 40 scanner, pictured in Figure 1 to our lab. Some of its characteristics:

• X-ray source: Sealed, air-cooled: 30-70 kVp/20-50 keV (160 µA)

• Detector: 2048 x 256 elements, 24 µm pitch

• Resolution: 3 – 72 µm nominal isotropic (pixel size)

• Image matrix: 512 x 512 to 4096 x 4096 pix

• Max. specimen size 36.9 x 80 mm (ØxL)

For ease and consistency, methods (so-called profiles) have been developed for medium and high-resolution CT-scans and for different pearl sizes. Our gemmologists commonly work with short movies generated from the virtual tomographic slices in the three independent planes (XY, XZ, YZ). In these movies, they can dynamically check any suspicious three-dimensional feature, indicating either natural formation or a possible human intervention in the pearl-growing process.