Beware: Laser Damage in Sapphires due to Jewellery Repair

by Dr. M. S. Krzemnicki first published in Facette 25 (February 2019)

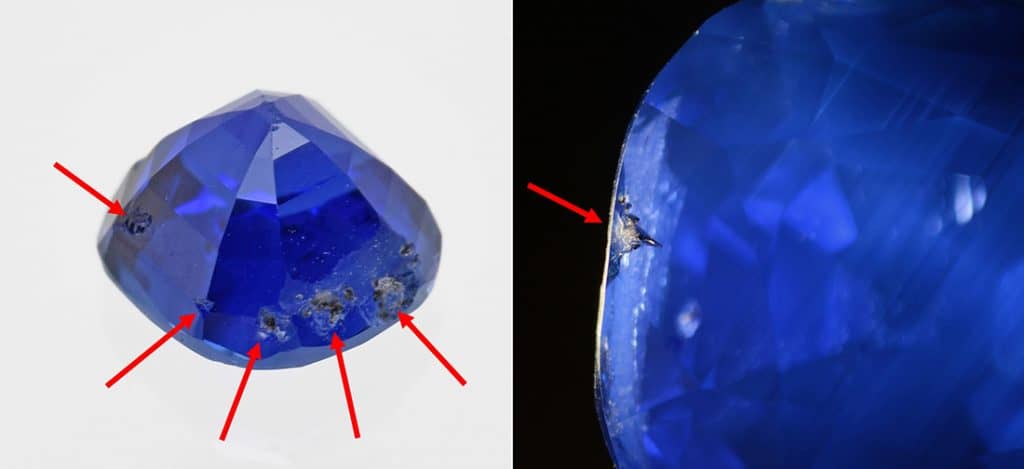

Having personally tested gemstones for more than 20 years now, the author of this short note was quite shocked in recent months to see distinct laser damage features on quite a number of sapphires (Figure 1) which were submitted to us by different clients. This is even more startling, as we (and other labs) also use lasers for trace element analysis of gemstones but take great care to ablate only the slightest amount of material at the girdle (laser spots of 0.05-0.1 mm diameter) in a very controlled manner. Most of these sapphires with laser damage are actually of high quality, often originating from Kashmir, and were presumably originally set in jewellery years or decades before being submitted as loose stones to SSEF for testing.

As a main characteristic, we have observed in all investigated cases more or less deep laser drill holes surrounded by tension cracks and prominent chipping. These laser damage features were always located on the pavilion side and close to the girdle of the stones (Figure 2). This leads us to assume that they were unintentionally created when trying to repair a jewellery item set with one of these sapphires, but using an inappropriate and much too powerful laser (soldering) equipment. So far, we have observed this laser damage only in sapphires, although similar features may occur in principle in any ruby or further colour variety of corundum during repair of a jewellery item.

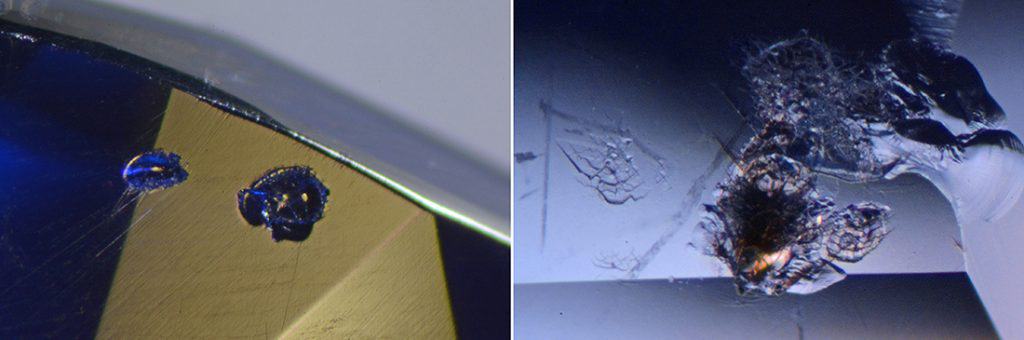

The conical shape of the laser holes is due to the confocal geometry of the laser beam after it was focused through a lens onto the item. Because of the very high temperatures locally created by the laser at the surface of the stones, we see effects of melting and volume expansion, leading to tension cracks and chipping features. Within the conic laser holes, we observe glassy residues formed as a result of the local melting of the stone by the high laser energy (Figures 3 and 4).

Although not a treatment, and certainly unintentionally created, these laser damage features are a rather unpleasant discovery. In many cases it requires considerable recutting and as a consequence results in weight (and value) loss. This could have been easily avoided by using only appropriate laser equipment for jewellery repair. We thus urge the trade to carefully review their laser equipment before using it to repair any jewellery with gemstones or to set and unset a gemstone from an old mounting, in order to avoid damage.

Want to learn more about sapphires?

Sign up for our free online course: Introduction to sapphires