ASDI (Automated Spectral Diamond Inspection)

by J.-P. Chalain, first published in Facette 21 (February 2014)

In 2013, numerous trade-press articles and gemmological laboratory alerts warned the diamond industry about the presence of synthetic diamonds mixed together with, or presented as, natural diamonds. These announcements pointed out that not only large diamonds, but also stars and melees are of concern. For simplicity in this article, we will name these two different categories “melees”. Melees are generally regarded as round cut diamonds with a diameter of less than 3.8 mm.

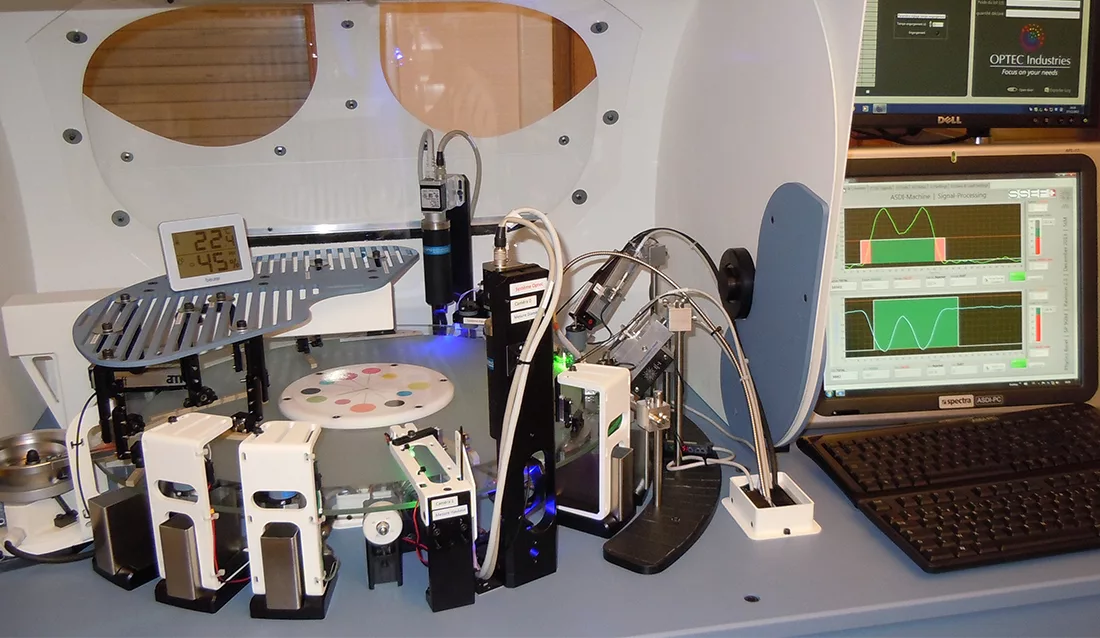

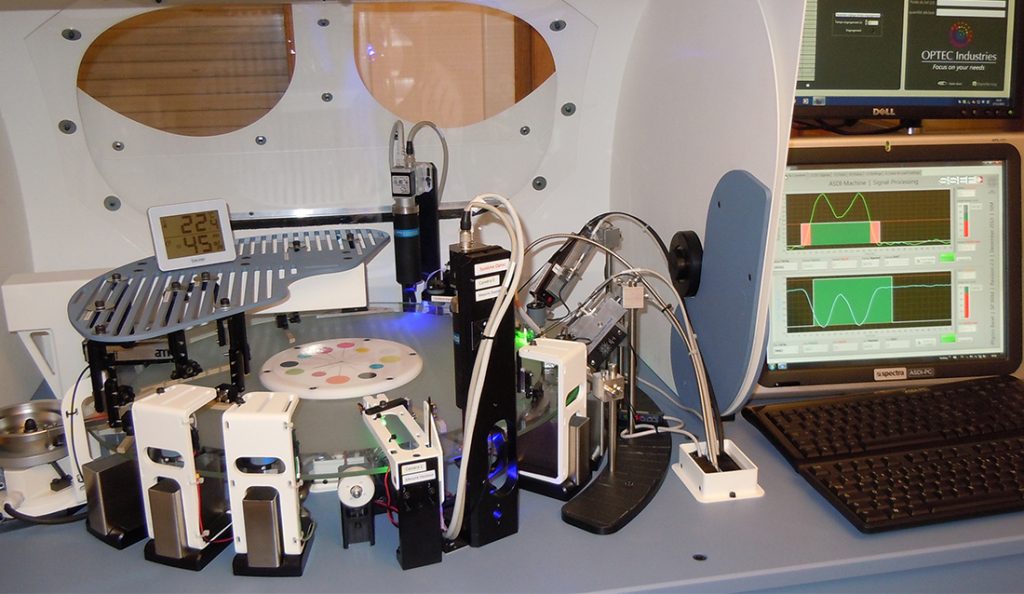

The SSEF already foresaw these developments in 2007. This was a period that saw the arrival in the trade of larger quantities of synthetic diamonds and of synthetic diamonds that were no longer detectable based only on their specific UV fluorescence reactions. Thus, SSEF decided to develop a machine called ASDI, an acronym for Automated Spectral Diamond Inspection.

The goal of this ASDI machine was to serve the Swiss watchmaking and jewellery industry. We wanted to develop a fast and efficient solution to control and authenticate industrial quantities of colourless melee batches (up to several million melees per month in Switzerland). The aim of this machine is to authenticate the natural origin of melee diamonds and thereby keep synthetic melee diamonds out of the supply chain. The ASDI machine does this in two ways. Firstly, by automatically detecting and sorting out any colourless diamond imitation that might be present in a batch. Secondly, by automatically detecting and sorting out of any possible colourless synthetic diamond and any possible colourless HPHT treated diamond.

The instruments used in this machine have been used at SSEF for diamond testing for many years. Together with Michael Steinacher, an electronic engineer at the University of Basel, we adapted these techniques to the requirements of the ASDI machine. A Raman probe is used for characterizing diamonds versus diamond imitations. The inelastic scattering of diamond’s carbon lattice gives rise to a characteristic diamond Raman peak at 572.6 nm. A short wave UV (SWUV) spectrometer is used for characterizing the SWUV transparency of each diamond. Colourless synthetic diamonds are of type II and HPHT treated diamonds are either of type II or of type IaB. Both types are typically transparent at SWUV. Thus, if a diamond is not transparent to SWUV, it is of natural origin.

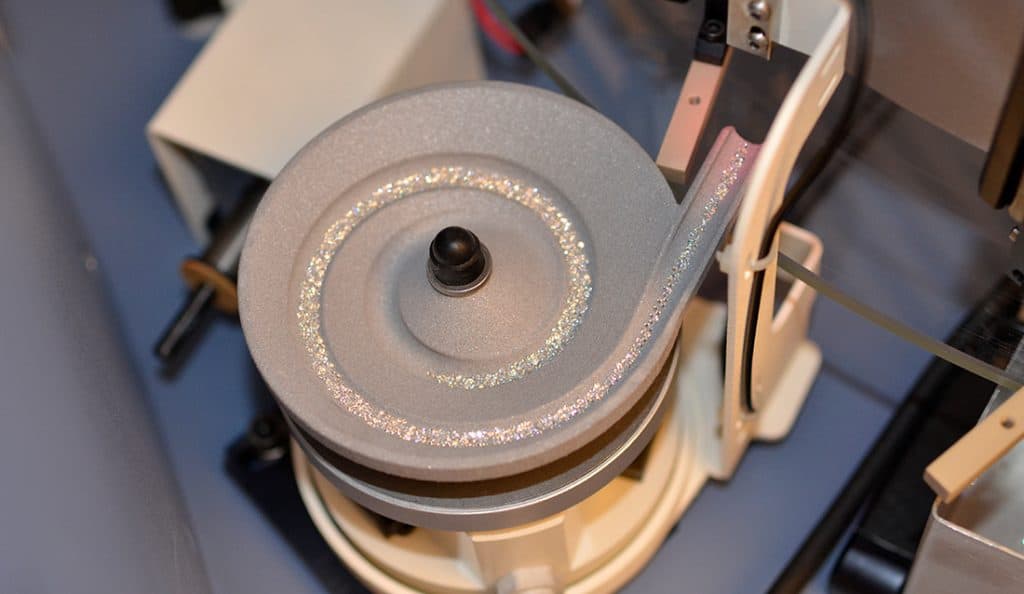

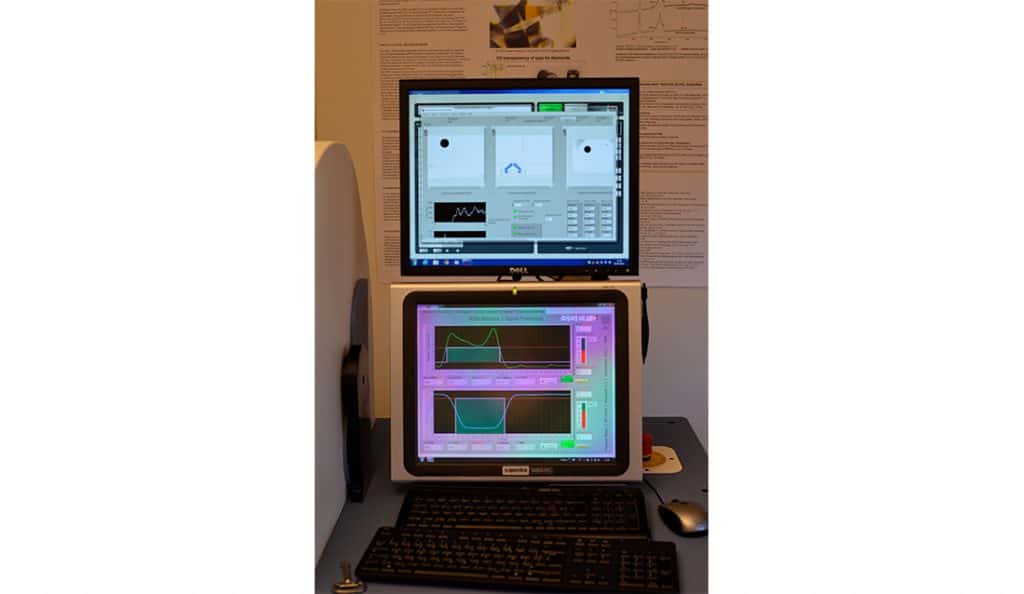

In 2011, a prototype of ASDI was finally installed at the SSEF, but was not yet automatised; therefore, each single diamond had to be manually placed on the rotating glass and results were only displayed on two oscilloscopes, resulting in stones having to be sorted out manually. More than 10’000 melees were tested in such a way until June 2013. With this, SSEF gained unique experience with the testing of large quantities of melee diamonds. Each time a totally- to slightly- transparent SWUV transparent diamond was detected, it was first checked by infrared absorption spectrometry to evaluate nitrogen concentrations and secondly for its low-temperature photoluminescence features.

Not one synthetic diamond was found, except one CVD synthetic diamond of 1.2 mm that was inserted on purpose into a tested batch by the director of the SSEF diamond department, as a way of imposing a blind test on the ASDI operating team. The ASDI machine easily detected this CVD synthetic diamond.

The electronics achievements required for the ASDI machine to function are impressive. For example, the power of the Raman signal, measured in only 30 milliseconds, is about 70×10-12W or 0,000 000 000 070 Watt). The electronic signal is treated in real-time. A built-in electronic algorithm pilots the electromagnetic arms that are responsible for sorting out diamond versus diamond imitations and SWUV transparent diamonds versus SWUV non-transparent diamonds with incredible reliability and speed.

For mechanical reasons, the use of the machine is restricted to melees with a diameter ranging from about 3.8 mm to 1.0 mm. The ASDI machine enables a testing rate of about 3’000-4’000 stones per hour once the combined analytical spectrometers – Raman and SWUV – have been successfully tested for their reliable and precise functioning.

In addition to the authentication of melees provided by the SSEF analytical spectrometers, a series of two OPTEC cameras and an OPTEC built-in software gives 14 measurements for each individual authenticated diamond (maximum and minimum diameter, percentage of ovalisation, table size and percentage, crown size, percentage and angle, pavilion size percentage and angle, girdle thickness, etc.).

In September 2013, SSEF applied for a patent and four machines have been pre-ordered from SSEF and are being manufactured. In conclusion, based on thousands of tests performed by SSEF, the ASDI machine is a very efficient, fast, reliable and robust solution to overcome the unavoidable arrival of small colourless synthetic diamonds in the diamond trade. As of January 2014, the ASDI machine in place at SSEF has already authenticated more than 400’000 melee diamonds.

Want to learn more about diamonds?

Sign up for our free online course: Introduction to diamonds