Sub-surface laser inscription and marking of gemstones

by Dr. L.E. Cartier, first published in Facette 26 (May 2020)

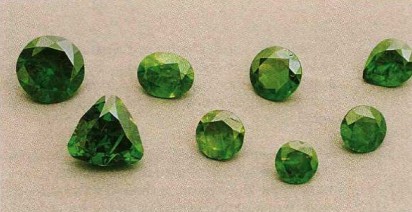

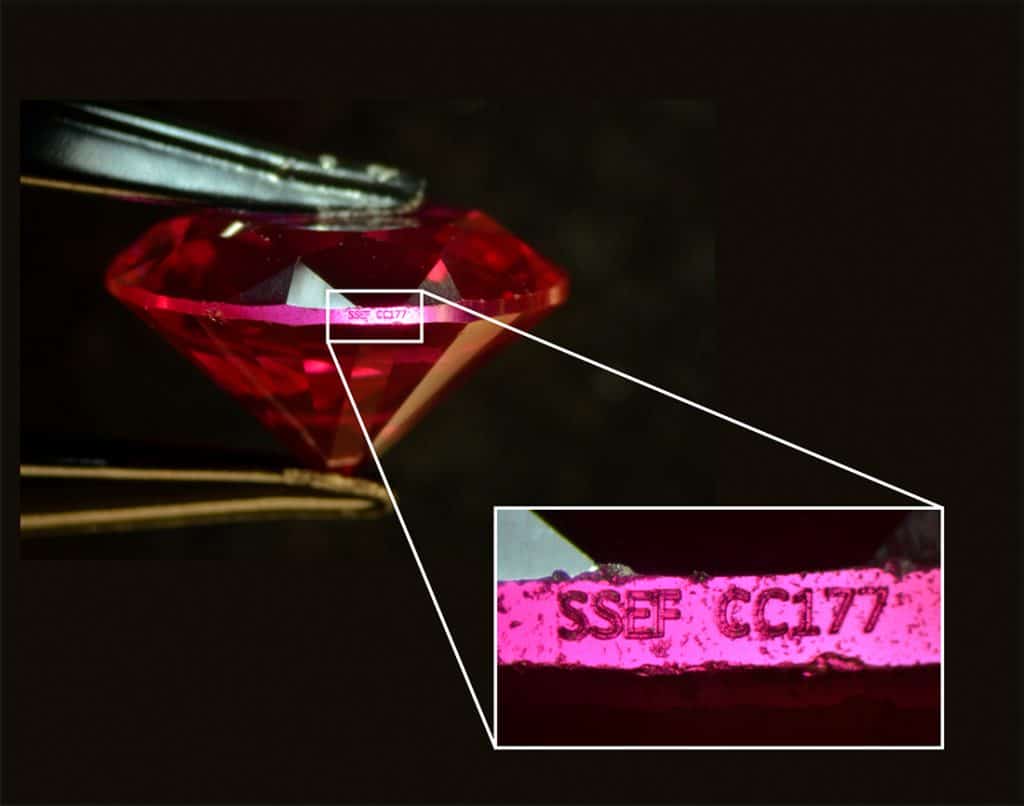

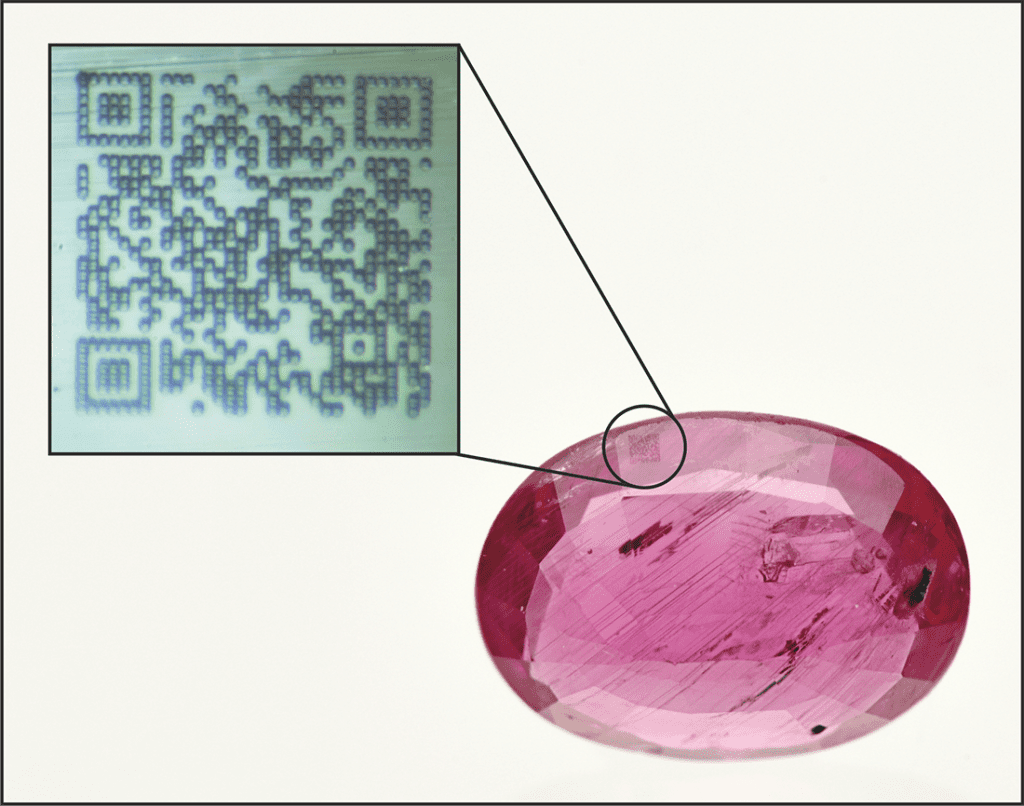

Inscription of diamonds and gemstones has been offered for several years, whereby a logo or a report number is inscribed on the girdle of a stone after cutting and polishing. This is done by some natural diamond sellers or grading laboratories and synthetic diamond manufacturers to document the provenance of such products (Eaton-Magaña and Shigley, 2016). It may also be done for coloured gemstones (Figure 1) and even pearls (Hänni and Cartier, 2013). The drawback associated with physically marking gems on their surface is the possibility that they may be re-cut and such markings thus lost. More problematic is the concern that surface marks may be fraudulently used or modified. This article seeks to present existing options and share results of a study recently carried out by SSEF with Opsydia Ltd., a spinout company from the University of Oxford that is specialized in sub-surface laser inscription of materials such as diamonds. In the context of this study, different coloured gemstones were marked with various forms of inscription at different depths below the surface. One advantage of such complex sub-surface laser marking technology is that it cannot be removed unless considerable material is cut and polished away. Additionally, there are significant challenges in sub-surface laser marking, decreasing the potential for fraudulent replication.

Surface Laser Inscription on Girdle or Table

Basic surface laser inscription (e.g. of a report number, logo or message, see Figure 1) of diamonds and gemstones on the girdle is quite common, and offered by a number of gemmological laboratories as a service upon a client’s request. Laser inscribing instruments are available on the market from companies such as Sarine (DiaScribe) and OGI (GemScribe). These laser inscription technologies remove material from the surface of the stone through an ablation process. After the material is removed, a trace of redeposited particles from the ablation process may be left in the trenches of the mark, which may increase its visibility. However, the surface nature of the inscription means that it may be completely erased by slight polishing.

QR Codes and Data Matrices for Additional Information

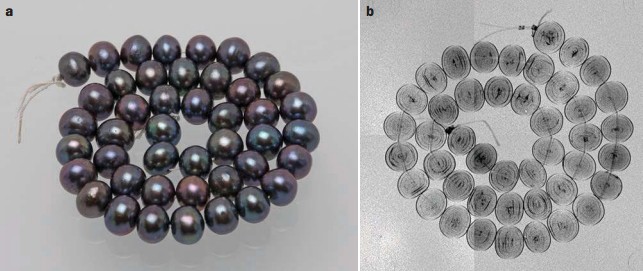

Many high-end gemstones today are tested using LA-ICP-MS technology (Wang et al., 2016). As part of this process, minute amounts of material are ablated from the girdle of a stone to provide detailed trace-element chemistry data, leading to additional information for treatment detection and geographic origin determination. Rather than ablate minute laser pits, GemTOF technology developed at SSEF enables us to carry out the test while at the same time creating a QR (quick response) code of the ablated area (Figure 2). The inscription of such a QR code can link to further information about a stone that is accessible to consumers. The advantage of such testing is that it requires no extra material to be ablated (i.e. the amounts ablated are insignificant such that a stone does not appreciably change in weight).

Sub-Surface Laser Inscription Experiments

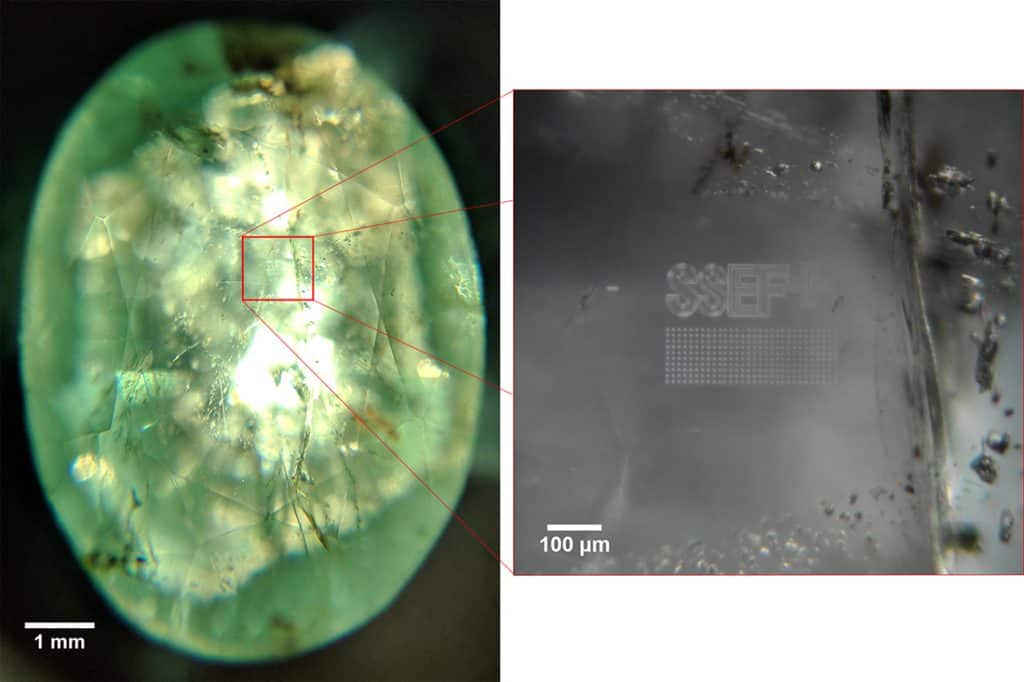

In the collaborative study by SSEF and Opsydia Ltd., sub-surface laser marking was investigated for coloured gemstones. This technology has been developed for both natural and laboratory grown diamonds and is already being applied by De Beers for Lightbox laboratory grown diamonds. Using this technology, the laser marks are customizable in shape, size and location; the laser process parameters can be tuned to create marks visible through a 10x loupe, or to be much smaller and only visible through a high magnification microscope, such that the clarity grade of a diamond, for example, is unaffected. The laser pulses used are less than a trillionth of a second (sub-picosecond) in duration, allowing accurate sub-surface marking of features with dimensions below a micrometer. All fabrication takes place within the laser focus, with no modification to the diamond surface or surrounding regions. The feature visibility can be altered using different sets of laser parameters for fabrication and features may be arbitrarily placed in three dimensions.

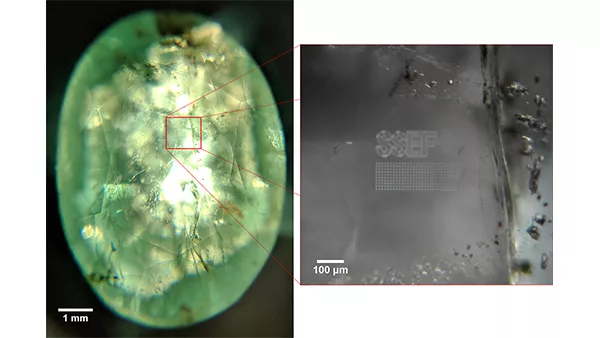

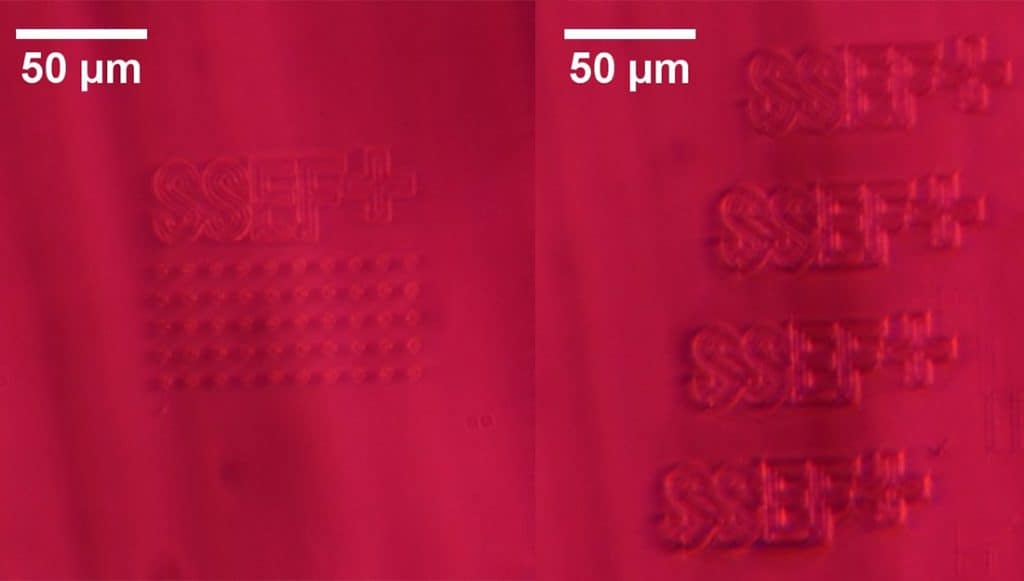

For coloured gemstones, different modification regimes were investigated for this study. The marks were checked offline using a laboratory microscope. Testing demonstrated that markings could be created with various visibilities. The high-precision sub-surface laser process has been successfully demonstrated to reliably create 1μm sized features up to 250μm below the surface of all coloured gemstones tested. In the case of the ruby and emerald samples (Figures 3 and 4), larger geometric features comprised of lines have been demonstrated, with two modification regimes identified for writing marks in this study: a weak change, which is only visible as a small refractive index modification, and a stronger effect causing lattice disruption.Both the index change and lattice disruption modification regimes offer promising development opportunities, leading to ultra-precise marks that do not affect the integrity of a gemstone:

- Index change—robustly creates controllable, faint marks that have no effect on the surrounding crystal structure. Future work would focus on developing a customer specific mark compatible with illumination and detection methods.

- Lattice disruption—robustly creates more visible marks, with some effect on the surrounding crystal structure (see Figure 4 for examples). Future work could focus on creating customized laser control schemes to constrain the modification to the desired mark geometry.

The advantage of sub-surface laser inscription is that the marker sits below the surface, which prevents the easy removal of the marker. As seen in our preliminary tests, the laser inscription may purely involve changing the refractive index of the material, without any lattice breakdown or removal of material. Therefore no trace of redeposited particles can be observed at the boundaries of the features, generating a barely visible mark.

The lattice disruption regime is accessed using a higher range of pulse energy from the fabrication laser, causing not only change in refractive index, but also lattice breakdown at a microscopic scale (without compromising the stability of the gem). As shown in the right-hand image of Figure 4, these stronger modification marks are more visually perceptible compared to those produced by the index-change method. When compared to surface laser inscription, such a sub-surface inscription technique offers potential for more secure marking in coloured gemstones while still being invisible through a loupe.

Conclusions

While the methods outlined in this article are not currently being offered as a standard service for coloured gemstones, such protocols are becoming increasingly feasible due to the rapid developments in technology. One major issue to be addressed with coloured gemstones is the large variability in the purity of stones, and thus standardizing the location of laser marking so that it become easily visible. Heavily included or fractured stones make sub-surface laser markings more difficult for a user to localize and recognize. We also note that there are a whole range of issues pertaining to the accountability and veracity of the information documented by such technology, but that goes beyond the scope of this article and will be addressed elsewhere. Meanwhile, we look forward to continuing our research in this technology development and providing secure marking solutions that are widely applicable for the gemstone trade.